Container plywood manufacturer

To ensure the quality of container plywood, all original material is well controlled.

Container plywood manufacturer. We cut log, shear veneer, press plywood, make glue.

There is a full set of test equipment. We check the glue every day, test the performance of plywood for each batch.

As a manufacturer, we got BV, FSC, ISO 9001, ISO 14001 certification.

Personalized Customization. We offer both bamboo and wood plywood of different sizes, different surface, and different request.

how container plywood manufacture

How container plywood manufacture? Here shows you a simple process of container plywood, to know more, please click related blog in our web site.

01.

Log cut.

We cut logs from our owned forest.

02.

Shear

All logs should be sheared to different size of veneers.

03.

Dry

We strictly control the moisture of veneer. Veneers are put into drying machine.

04.

Glue & Assemble

The glued veneer are assembled according to the technical request. Enough glue is very important for container plywood.

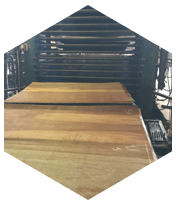

05.

Press

It’s an important step in container plywood manufacture.

06.

Cut & Chamfer

We cut and sand plywoods, make chamfers in one line.

07.

QC

All plywood will be check piece by piece.

08.

Packing

We pack plywoods as customers’ requirement.